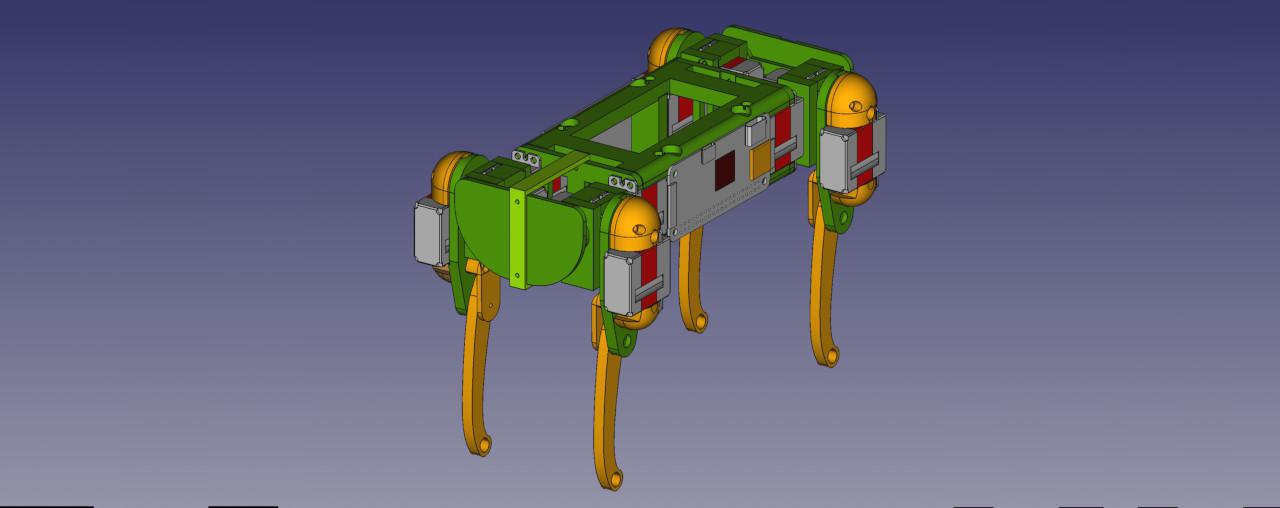

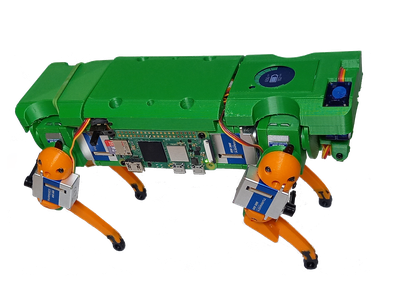

After watching many videos of Boston Dynamics Spot, Unitree A1 and similar, all have one thing in common - their body is slick and narrow, while Flig's first prototype more like square. Flig's legs in this format are equally distanced front to back and left to right. So, after a few sessions with FreeCAD here's what I've got to:

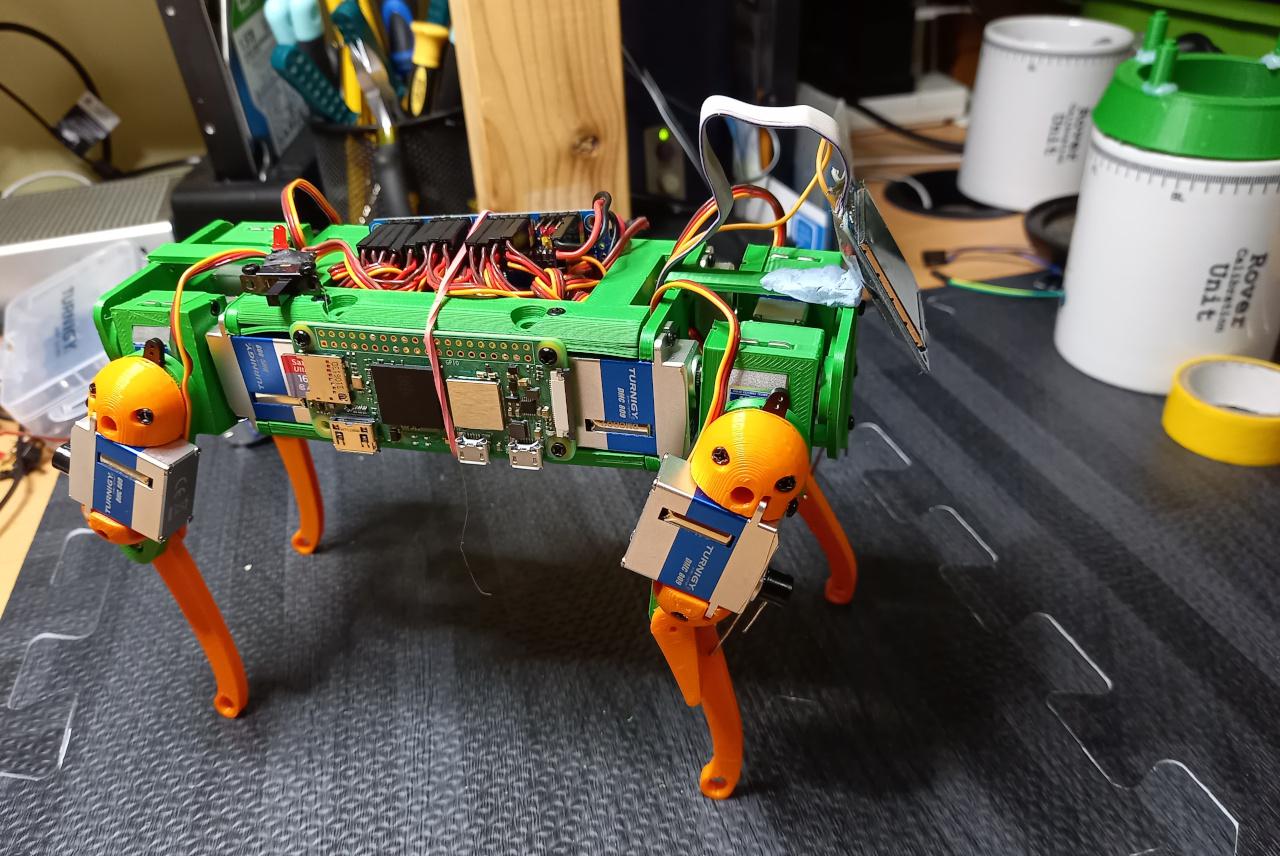

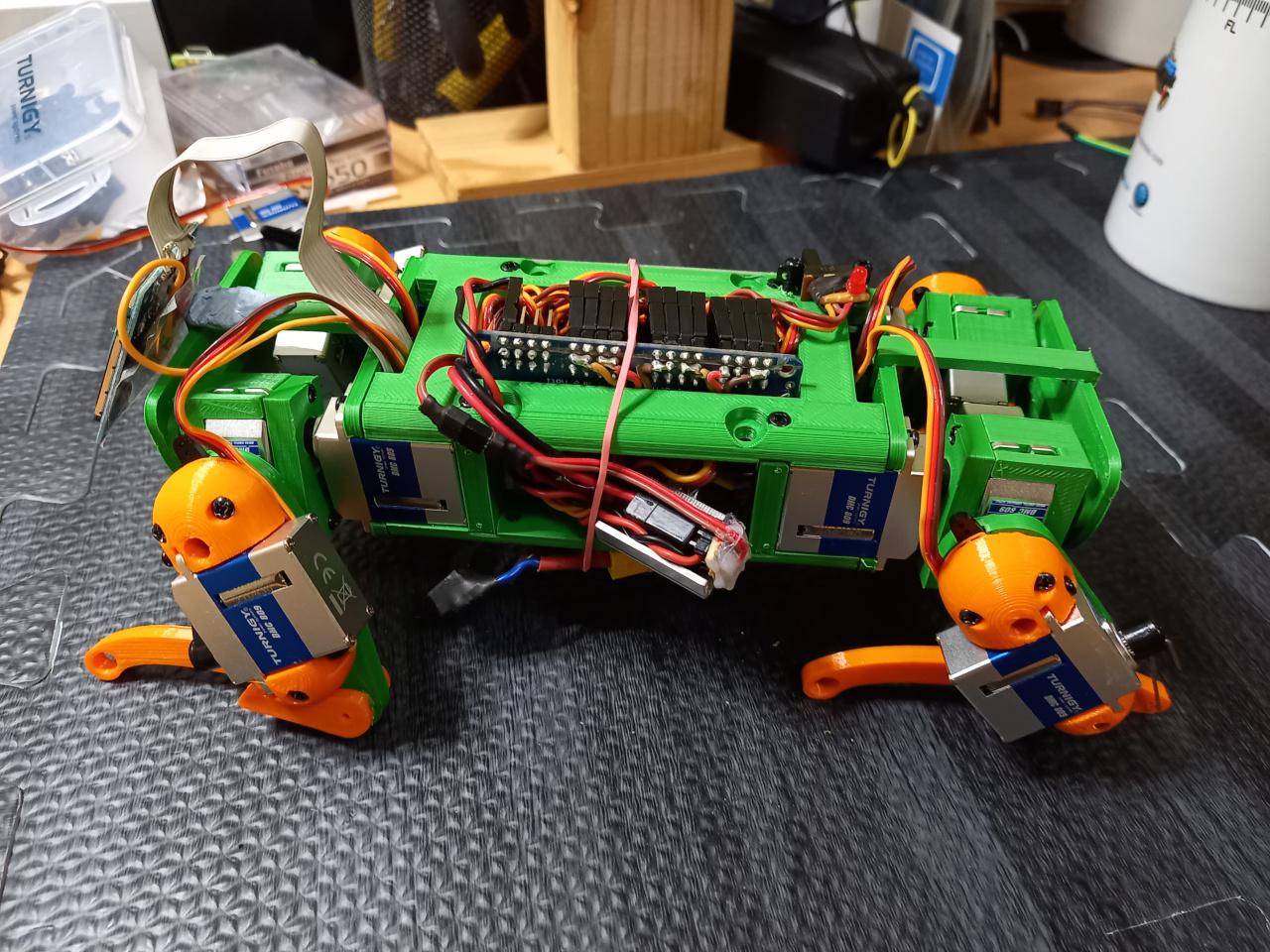

Now, with some 3d printing and replacing HXT900 servos (0.12s/60º at 5V with nylon gears) with Turnigy DMC 809 - metal gears 0.08s/60º at 5V (or 0.07s/60º at 6V) - Flig is going to be stronger and faster.

And it turned out to be much, much quieter!

Also, sides were designed to carry PiZero sized Raspberry Pis - PiZero2W in this case. Two Raspberry Pis are going to be connected with USB. Second Raspberry Pi is going to be working as an OTG Ethernet device so communication between them is going to be through USB-2.

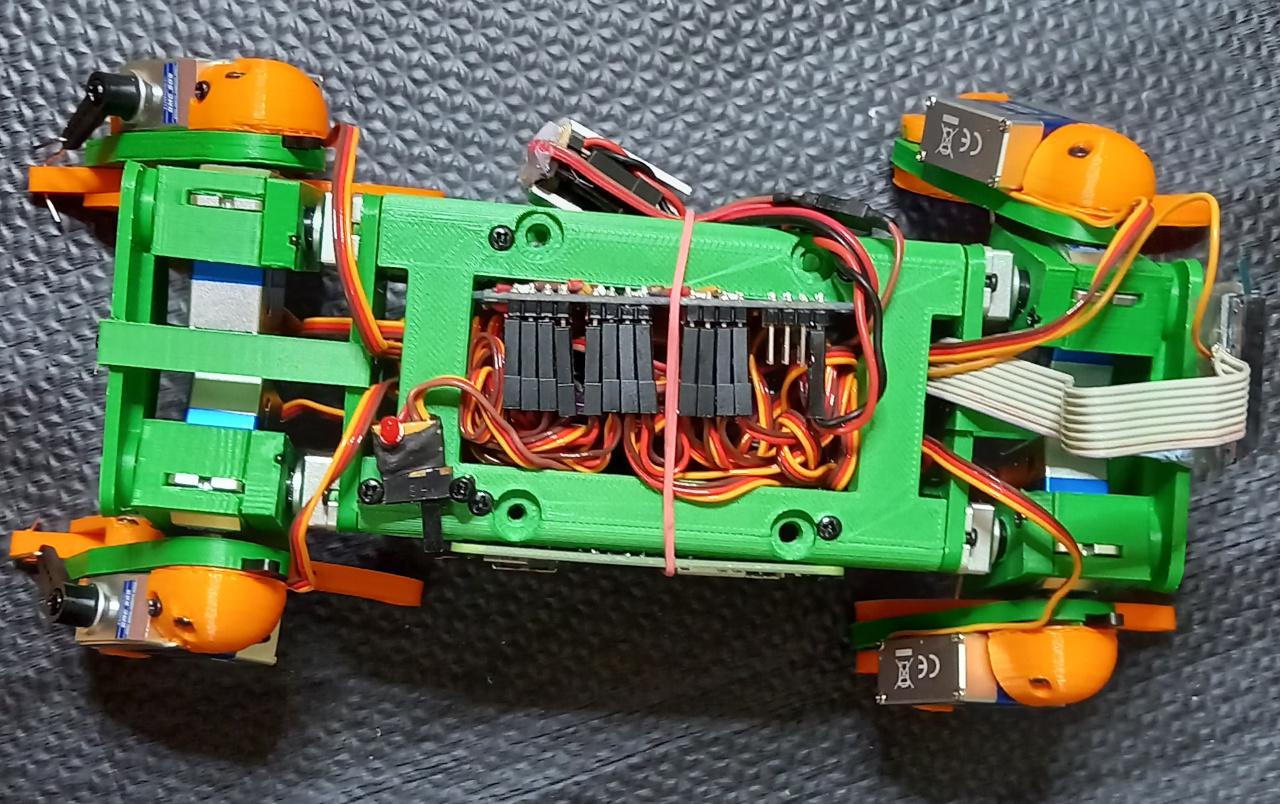

Inside, there's exactly enough space for a PCA9685 breakout board, two sandwiched INA321, MosFET, connectors, two BECs and servo wires. The display is going to be on the top of the front legs.

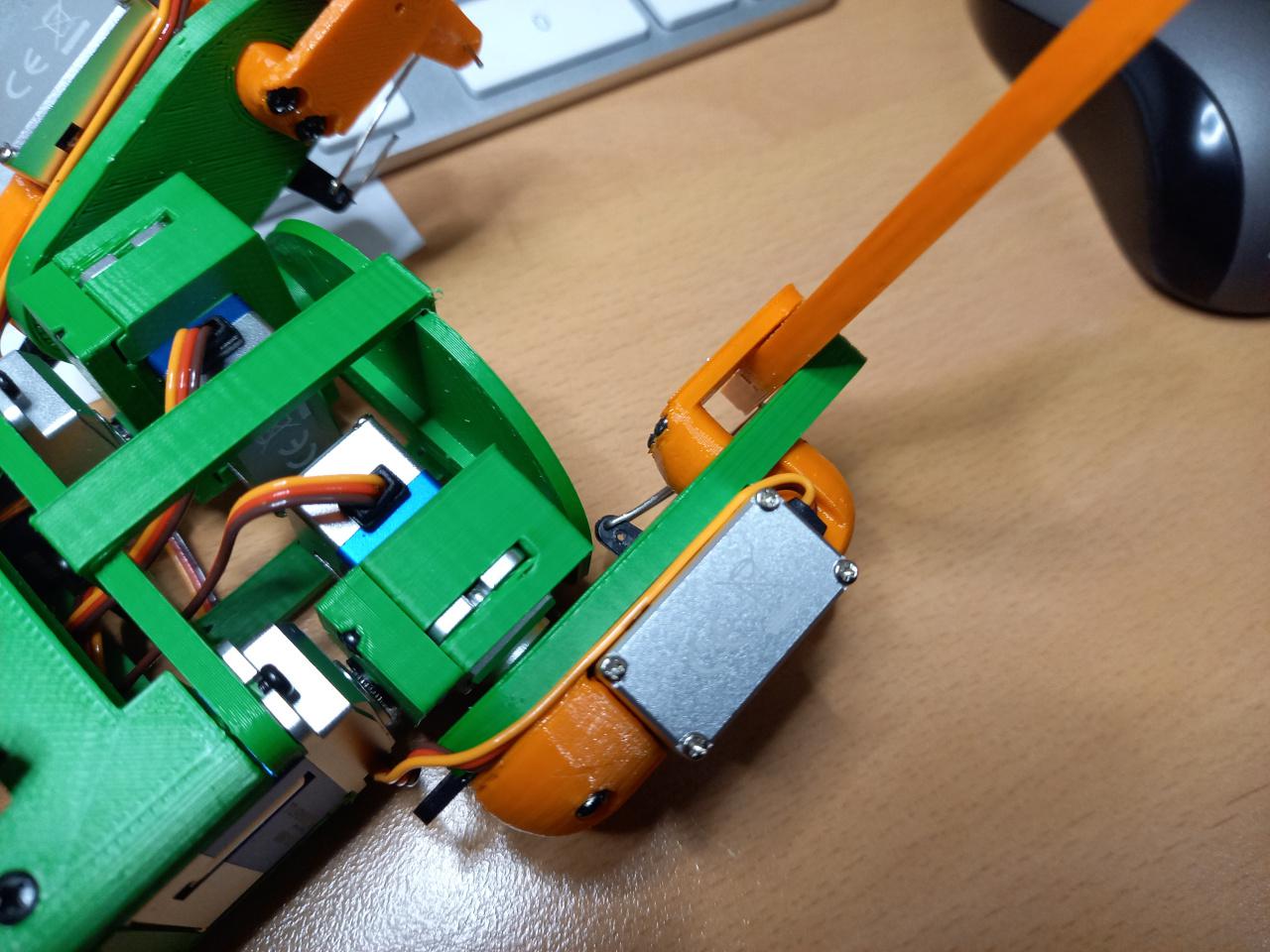

The first design had a flaw - both front and back legs were made the same - so servo arms ended up catching the frame. For instance back legs were fine:

while the front legs' servo arm was on the wrong place:

To fix it all that was needed is to change where legs are going to be driven from - in case of front legs it would need to go to the front.

When fixed it all looked like this:

F. L. I. G.

F. L. I. G.

Comments

Comments powered by Disqus